Knowing the features and capabilities of linear actuators gives you an edge in your project. You may need a linear actuator with a lightweight, compact design and excellent rigidity – or one that requires long-term, maintenance-free operation. In this article we will discuss some of the strengths and advantages of various linear actuator options and their benefits to functionality.

Knowing the features and capabilities of linear actuators gives you an edge in your project. You may need a linear actuator with a lightweight, compact design and excellent rigidity – or one that requires long-term, maintenance-free operation. In this article we will discuss some of the strengths and advantages of various linear actuator options and their benefits to functionality.

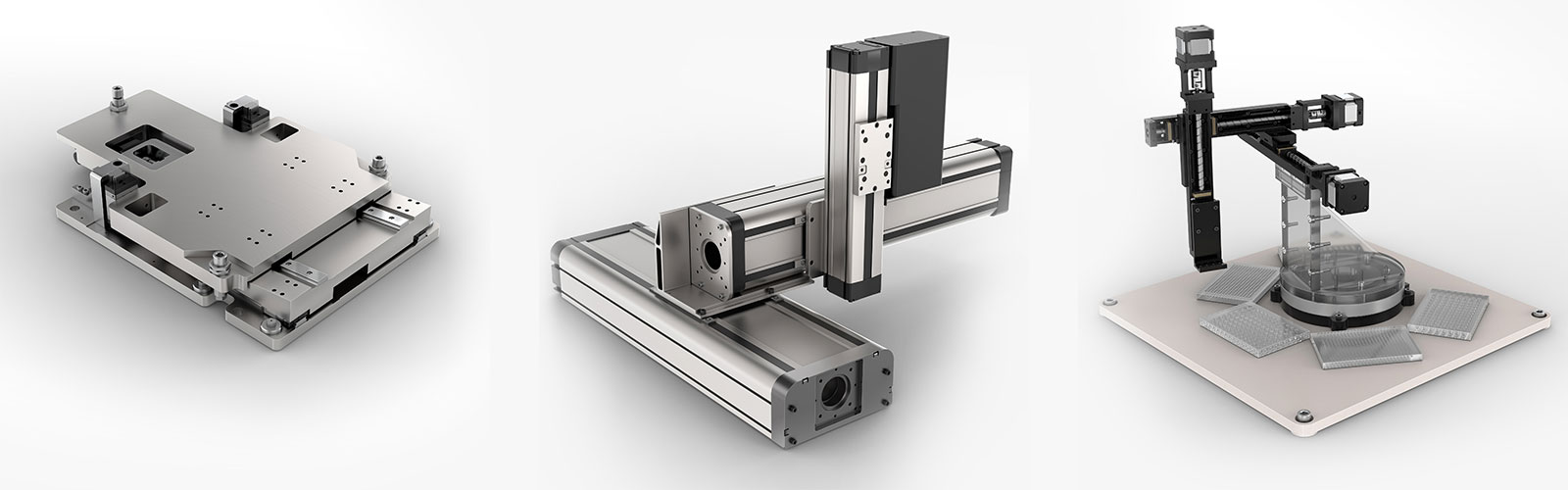

A Linear Actuator in an All-in-One Structure Reduces Both Design and Installation Time

Advances in technology and innovation have enabled automation in linear motion on an unprecedented scale. The ability to integrate a ball screw, linear guide, and support bearings has resulted in the capability to produce a robust, compact single-axis linear actuator. An all-in-one actuator design means greater efficiency through the reduction of time spent on project design and layout. Multiple datum planes, the bottom and a lateral side of the rail result in very accurate installation and reference edges. Models with pin holes are also available and come standard. It is possible to immediately operate the linear actuator after installation and run-in due to the presence of pre-packed grease.The combination of design efficacy and accuracy of installation is a strong consideration for your linear actuator needs.

Linear Actuators With Anti-Rust Capability

In some applications, rust can be a detriment to the functionality and life-long durability of the assembly. A linear actuator which has any amount of rust will have reduced ability to operate or even fail. You will want to select a linear actuator that features rust prevention by temperature chrome plating which is used on the bodies and sliders of the linear actuator. This creates a rust-resistant effect and preserves the durability of the unit. Note that this comes standard on NSK Linear Actuators.

Ensuring Long-Term, Maintenance-Free Operation

A lubrication unit on the linear actuator helps promote smooth lubrication performance for extended periods of time, including in mechanical environments where lubrication is difficult to apply or where varying mounting options are a critical necessity. The K-1 lubrication unit also has the capability to lubricate in applications where the use of oil is not permitted because of hygienic issues, or where mechanical equipment requires a high degree of washing out. Lubrication units for food processing is available in situations where compatible material under FDA regulations is a necessity.

Of course, maintenance to replenish preceded grease obviously does extend the life of a linear actuator, but even without this step, you may use it for 5 years or 10,000 km depending on your application, whichever comes first, with or without maintenance.

When considering linear actuators, these strengths contribute to ensuring the extended fatigue life of the linear actuator is maximized, that design and installation time is minimized to the fullest extent possible, and also will require a lower or nonexistent degree of repair and/or maintenance regardless of application category. An extended lifetime with less maintenance will translate in the end to increased profit and productivity at less cost. Don’t hesitate to contact NSK Automation to obtain your quote for Linear Actuators.