A linear bearing aims to work with the linear rail or guide shaft to provide low friction movement in a single direction while “bearing” the load. Linear bearings are part of linear motion systems in many industries and applications.

A linear bearing aims to work with the linear rail or guide shaft to provide low friction movement in a single direction while “bearing” the load. Linear bearings are part of linear motion systems in many industries and applications.

Types of Linear Bearings

Several types of linear bearings can be used within a linear motion system. When building your system, you will need to look at your needs to determine which bearing is best for your application.

Plain Bearings

Plain linear bearings are used in many applications requiring linear motion systems.

Features of Plain Bearings:

- Simplicity: Plain bearings, sometimes called bushings, have a simple design without any rolling elements, making them easy to manufacture and maintain. Instead of rolling, plain bearings utilize a sliding motion. Plain bearings are often available at a lower initial cost than other options, making them an attractive choice.

- Self-Lubrication: Many plain bearings are self-lubricating, reducing the need for external lubrication systems, which will reduce maintenance needs and ultimately reduce downtime.

- High Load Capacity: Plain bearings can handle heavy radial loads and moderate axial loads, making them suitable for various applications where load capacity is a concern.

Applications for Plain Bearings:

- Automotive Industry: Plain bearings are used in engine components, suspension systems, and gearboxes due to their ability to handle high loads and resist wear.

- Industrial Machinery: Plain bearings are commonly used in conveyor systems, pumps, and compressors due to their durability and load-bearing capacity.

- Construction Equipment: Plain bearings can be found in applications like cranes, excavators, and bulldozers where heavy loads and rugged conditions are present, as they are able to handle the heavy loads.

- Home Appliances: Plain bearings are used in many different home appliances used by consumers. Plain bearings are found in washing machines, refrigerators, and air conditioners for their simplicity and reliability.

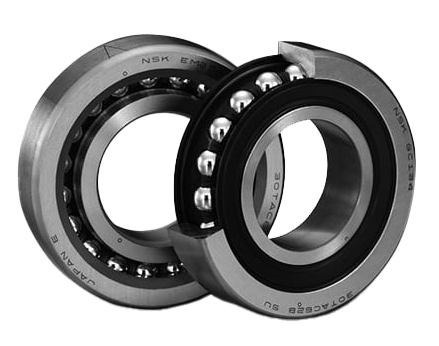

Rolling Element Bearings

Unlike plain bearings that operate with a sliding motion, rolling element bearings use a carriage with more room for balls or rollers that fill the space and support the linear motion. When compared to plain bearings, rolling element bearings are less dependent on external operating conditions and require less maintenance.

Unlike plain bearings that operate with a sliding motion, rolling element bearings use a carriage with more room for balls or rollers that fill the space and support the linear motion. When compared to plain bearings, rolling element bearings are less dependent on external operating conditions and require less maintenance.

Features:

- Rolling Elements: As the name indicates, rolling element bearings consist of balls or rollers that roll between two surfaces (the carriage and the linear guide) to reduce friction and distribute loads, enabling smoother motion than other bearing types.

- Low Friction: Rolling element bearings have significantly lower friction than plain bearings, resulting in higher efficiency.

- Precision: Rolling element bearings offer precise rotational motion due to reduced contact surface and rolling elements.

Applications:

- Electric Motors: Rolling element bearings are essential for electric motors, ensuring smooth rotation and minimal energy loss. Rolling element bearings are an important part of most electric motors, as they allow the shafts and axis to rotate at high speeds with minimal power loss by drastically reducing friction. Several options for rolling element bearings are possible for electric motors.

- Machinery: Rolling element bearings are commonly found in gearboxes, machine tool spindles, and turbines due to their high load capacity and low friction. As with electric motors, rolling bearings allow for high speeds.

Thrust Bearings

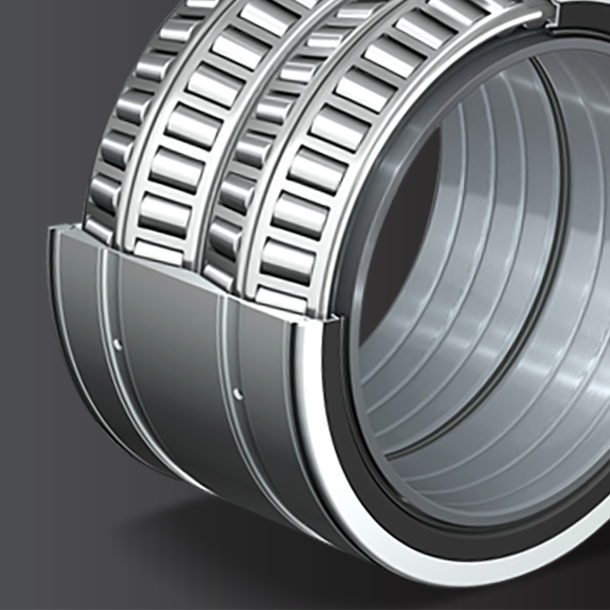

A thrust bearing is a specific type of bearing that rotates between parts but is designed to support predominantly axial loads. There are several types of thrust bearings, including thrust ball bearings, cylindrical thrust roller bearings, tapered roller thrust bearings, spherical roller thrust bearings, fluid bearings, and magnetic bearings. All support axial loads but have slightly different constructions designed for specific applications.

A thrust bearing is a specific type of bearing that rotates between parts but is designed to support predominantly axial loads. There are several types of thrust bearings, including thrust ball bearings, cylindrical thrust roller bearings, tapered roller thrust bearings, spherical roller thrust bearings, fluid bearings, and magnetic bearings. All support axial loads but have slightly different constructions designed for specific applications.

Features:

- Axial Load Capacity: Thrust bearings are designed to handle high axial loads, allowing them to support heavy loads in an axial direction.

- Minimal Friction: These bearings minimize friction during axial movement, ensuring efficiency in applications with directional force.

Applications:

- Automotive Transmissions: Thrust bearings are used in manual and automatic transmissions to support axial loads generated by gears and shafts.

- Heavy Machinery: Thrust bearings are found in applications like bulldozers, cranes, and excavators, supporting the vertical loads generated by heavy equipment.

- Wind Turbines: Thrust bearings are crucial components in wind turbine systems, handling the axial loads generated by the rotor’s rotation.

- Marine Industry: Used in ship propulsion systems to handle the thrust generated by propellers, thrust bearings ensure efficient movement through the water.

Linear Bearings

All linear bearings are designed to provide free motion in one direction with low friction. Linear bearings can be designed and manufactured to specific dimensions, making them highly customizable for applications that require high precision and accuracy.

Features:

- Linear Motion: Linear bearings facilitate motion in a straight line, enabling precise and controlled movement.

- Variety of Designs: Linear bearings come in various designs, including ball bearings, roller bearings, and plain linear bearings catering to specific application needs.

- High Precision: Linear bearings offer high precision and repeatability in linear movements making them ideal for applications requiring accurate positioning.

Applications:

- 3D Printing: Linear bearings are essential in 3D printers, guiding the print head’s precise movements along the X, Y, and Z axis where smooth, low-friction, and accurate movement is required.

- Factory Automation: In automated manufacturing processes, linear bearings enable smooth and accurate movements in robotic arms and conveyor systems.

- Medical Devices: Linear bearings can often be found in medical imaging equipment, robotic surgery systems, and laboratory automation, ensuring precise and stable movements in critical medical applications.

- High-Precision Machinery: Linear bearings are often utilized in semiconductor manufacturing equipment, CNC machines, and metrology tools for their ability to provide precise linear motion in micron-level increments.

Advantages of Linear Bearings:

There are many advantages to using linear bearings as part of a linear motion system where smooth motion is required. Some of the advantages include:

- Low Friction and Reduced Wear – Linear bearings reduce the friction of a linear motion system, which ultimately reduces wear and stress along the linear guide.

- High Load-Carrying Capacity – Linear bearings are able to support high loads, which is necessary for many industrial applications.

- Precision and Accuracy in Motion – Linear bearings allow for excellent precision and accuracy. Medical and robotic applications use linear bearings for this reason.

- Noise Reduction and Smooth Operation – When noise is a concern, linear bearings are the right choice for quiet and smooth operation.

- Cost-Effectiveness and Longevity – Linear bearings, after the initial investment, are long-lasting and durable with little maintenance requirements, making them extremely cost-effective in the long run.

Linear Bearings and Rails in Precision Engineering

Linear bearings and rails are the key components in a linear motion system for precise and low-friction linear movement. The stability that characterizes a linear motion system is made possible by linear bearings and rails.

Linear Bearings

Linear bearings are essential mechanical components that facilitate smooth and precise linear motion in a straight line. They are designed to support and guide the movement of objects along a fixed path. Linear bearings consist of a stationary and moving object, between which the bearing balls or rollers move, reducing friction and enabling efficient motion. These bearings are available in various designs, such as ball bearings, roller bearings, and plain bearings, each suited for specific applications based on load requirements, speed, and precision needs.

The key benefits of linear bearings are precise linear motion, reduced friction, and smooth motion. Because of these benefits, linear bearings and rails are essential in many different industries, but particularly the manufacturing, automation, and robotic industries. With many different designs, there is always a solution for specific application needs.

Linear Bearing Rails

Linear bearing rails are complementary components to linear bearings in linear motion or linear guide systems. Linear rails provide a stable, straight guiding surface along which the linear bearings can move. Linear rails are typically made from aluminum, steel, or stainless steel, offering durability and rigidity. These rails have precisely machined surfaces, ensuring smooth and accurate movement of the attached linear bearings. Linear bearing rails come in different profiles, including square and round, catering to diverse application requirements.

The key benefit of linear bearing rails over other options is the stable guiding surface they provide. The durable materials allow for longevity, which will ultimately reduce downtime. As previously stated, linear rails are available in different designs, but can also be customized for the exact needs of the application.

Collaborative Role in Applications

Linear bearings and rails work together. In practical applications, linear bearings are mounted onto linear bearing rails creating a linear guide system that enables controlled linear motion. The low-friction design of linear bearings allows them to glide smoothly along the rails providing precise movement for machinery and equipment. Linear guide systems made of linear rails and bearings are widely used in applications like CNC machines, 3D printers, automated manufacturing systems, and robotics where accurate linear motion is crucial for the performance and efficiency of the equipment.

Engineers and designers can create high-performance systems that offer stability, precision, and durability by combining linear bearings with properly matched linear bearing rails. This collaborative setup ensures machinery and automated systems can operate smoothly, delivering reliable performance for various industries.

Why Choose Linear Bearings Over Other Bearing Types?

With many different bearing types to choose from, the choice to use linear bearings in a linear motion system comes down to several different benefits that linear bearings offer over other options.

Precision and Accuracy

Linear bearings offer superior precision and accuracy in motion control compared to other bearing types. In applications where precision is critical, such as in medical equipment and high-tech manufacturing processes, linear bearings are the best choice to ensure the required level of precision and accuracy is obtained.

Low Friction and Reduced Wear

Linear ball bearings offer the lowest friction, offering a measurable reduction from other bearing types. As they have a low contact area with the guide, friction can be reduced significantly over bearings with sliding elements. Reduced friction has a substantial impact on energy efficiency and wear and tear leading to a longer lifespan and lower maintenance costs.

High Load-Carrying Capacity

Linear bearings can handle heavier loads without compromising performance, particularly in industrial applications such as assembly line robotics. By utilizing linear bearings, manufacturers can maintain high levels of efficiency and accuracy in their assembly processes. Linear bearings allow the robots to easily carry heavy components, ensuring the assembly line’s smooth operation.

Smooth and Quiet Operation

Linear bearings contribute to smooth and noiseless machinery operation due to the smooth motion and low friction they provide. In certain applications, such as in medical facilities or residential environments, the importance of quiet operation is key.

Customization and Adaptability

Linear bearings can be customized to fit specific requirements. Specialized bearings ensure the smooth operation of critical processes in environments where standard components may not suffice. Laboratory automation is pivotal in scientific research, diagnostics, and pharmaceutical development and often requires customized linear motion systems to fit the exact specifications. Linear bearings are extensively used in laboratory automation systems to ensure precise and reliable movements in various equipment, including liquid handling robots, sample analyzers, and high throughput screening devices.

Environmental Considerations

Although there are several different options for materials, many linear bearing materials are eco-friendly and sustainable, making them the “green” choice. In today’s world, making sustainable choices is critical for the long-term success of many industries.

Cost-Effectiveness and Longevity

There are many long-term cost benefits associated with linear bearings. After the initial investment in a linear motion system incorporating linear bearings, the maintenance requirements and costs are significantly reduced when compared with other bearing types. The longevity, durability, and reduction in downtime provided by linear bearings make them the most cost-effective option in the long run.

Applications of Linear Bearings

The significance of linear bearings lies in their ability to provide precise, smooth, and efficient linear motion, enabling a wide range of applications in fields such as manufacturing, automation, robotics, and healthcare.

Linear Bearings in 3D Printing

3D printing relies on linear motion systems to function. Linear ball bearings, when used in a linear motion system, provide a greater degree of precision and layer resolution, motion control, and will enhance print speed and quality. 3D printing involves a degree of mechanical stress, and using linear bearings will help to reduce these stresses. Many 3D printers require their linear motion systems to have a strong degree of rigidity, and linear bearings used with linear rails can provide the right support to keep the machine functioning most effectively.

Linear Bearings in Robotics

Linear bearings play a major role in the systems involved in robotics. Linear bearings are used in joint and actuator movements as well as robot arm functionality, which improves robot accuracy and efficiency. In addition, Robot Transfer Units (RTU) built with linear motion systems incorporating linear ball bearings allow robots to travel long lateral distances between multiple work areas. Robotics often place high demands on linear motion systems, and linear ball bearings are able to harness the benefits of smooth motion, high load capacity, increased precision, and the ability to function in a variety of environments to keep all robotic equipment functioning, minimizing downtime and increasing efficiency.

Linear bearings play a major role in the systems involved in robotics. Linear bearings are used in joint and actuator movements as well as robot arm functionality, which improves robot accuracy and efficiency. In addition, Robot Transfer Units (RTU) built with linear motion systems incorporating linear ball bearings allow robots to travel long lateral distances between multiple work areas. Robotics often place high demands on linear motion systems, and linear ball bearings are able to harness the benefits of smooth motion, high load capacity, increased precision, and the ability to function in a variety of environments to keep all robotic equipment functioning, minimizing downtime and increasing efficiency.

Linear Bearings in Autonomous Vehicles

Autonomous vehicles are the future of the automotive industry, and linear motion systems are critical to the success of these advances. Linear bearings are used in the systems that provide precision in autonomous driving, enhancing the safety and reliability of self-driving cars. They are also used in transmissions, engines, and perhaps most importantly, the steering and suspension systems that require a high degree of smooth motion, precision, and accuracy. Linear ball bearings used in self-driving cars can help the success of long-range navigation while improving the safety of these vehicles. High-quality linear bearings contribute greatly to the linear motion systems that make autonomous vehicles possible.

Linear Bearings in Injection Molding

Injection molding is ideal for small, complex projects that require a high degree of precision and high-quality results. Therefore, injection molding is another application that benefits greatly from linear motion systems that incorporate linear bearings. Linear bearings help to mold opening and closing mechanisms, assist with maintaining precise mold dimensions, and play a key role in improving molding speed and efficiency. Injection molding is known to be a faster process than other molding processes, and this is made possible by the linear motion systems that use linear ball bearings to enhance speed while not compromising the precision, low vibration, and accuracy of the movement.

Linear Bearings in Integrated Systems

System integration brings together many components involved in sub-systems to function together to create a coordinated whole. Linear bearings play an important role in complex machinery that is built on the concept of an integrated system. A linear motion system using linear bearings enables interconnected movements, which enhances overall system performance. Every integrated system component must function accurately and smoothly, and systems that incorporate linear motion systems are well equipped to work together. Using linear bearings within a linear motion system improves the individual system and strengthens the integrated system.

Linear Bearings in Laboratory Automation

Linear bearings used in linear motion systems in laboratory instrumentation and robotics will enhance accuracy in lab procedures enabling high-throughput automation. Linear bearings have been used in laboratory equipment for many years, and as advancements in technology bring more laboratory automation, linear bearings within linear motion systems are helping to improve the systems. Linear bearings are able to handle the high degree of precision and accuracy required in laboratory automation, and can function well in a laboratory environment since they are resistant to contamination and require a low degree of maintenance. Using lightweight materials for linear ball bearings can help reduce noise, vibration, and friction even more.

Linear Bearings in Medical Equipment

Linear motion systems are used in many medical equipment applications, and the advancement in linear systems has greatly improved both the patient and healthcare worker experience. Linear motion devices incorporating linear bearings are used in patient bed movements, surgical equipment functionality, precision in medical devices, and in scanning and imaging equipment. For all medical equipment, smooth, accurate, and low vibration and noise is critical to effective use, and the use of linear bearings can provide for those needs. All medical equipment is held to a high degree of regulation, and the advantages of linear bearings in a linear guide system can ensure efficient and effective use in the medical industry.

Linear Bearings in Medical Imaging

Linear motion systems are present in many applications in the medical industry. Medical imaging has always relied on linear motion. Linear bearings are used in linear motion systems for medical imaging devices such as MRI machines, X-ray machinery, and CT scanners. Precise linear motion is required for both diagnostic and treatment procedures in medical imaging. Linear bearings improve the functionality of this medical imaging equipment by reducing friction, vibration, and noise. By providing smooth linear motion, device movements are significantly improved which will enhance image quality and stability and provide a greater degree of precision in the imaging process.

Linear Bearings in Robotic Surgery

Minimally invasive procedures are becoming more accessible thanks to advancements in robotic surgery, which is beneficial to both patients and surgeons and allow for quicker recovery and more intricate techniques. Linear bearings provide smooth and precise movement of robotics arms and conveyors, making their safe use in medical procedures more of a possibility. Precision and safety cannot be compromised in any medical use, and linear bearings provide the accuracy and smooth motion necessary for surgical robotics. The reduction in friction, vibration, and noise provided by using linear bearings in the linear motion systems of surgical robots is important to their continued use.

Linear Bearings in Factory Automation

Linear motion products are used in high numbers in factory automation applications. Manufacturing requires a good deal of machinery to push, pull, lift, tilt, turn, and move objects, and linear motion systems are perfectly suited for the task. Linear bearings are used in conveyor systems, robotic assembly lines, and many other manufacturing processes. Technology is advancing rapidly in what is often referred to as the Industry 4.0 Revolution and linear bearings are a big piece of this technological shift toward more automated processes. Enhancing efficiency and reducing downtime are key in factory automation, and using linear motion systems with linear bearings are essential for this progress in manufacturing.

Linear motion products are used in high numbers in factory automation applications. Manufacturing requires a good deal of machinery to push, pull, lift, tilt, turn, and move objects, and linear motion systems are perfectly suited for the task. Linear bearings are used in conveyor systems, robotic assembly lines, and many other manufacturing processes. Technology is advancing rapidly in what is often referred to as the Industry 4.0 Revolution and linear bearings are a big piece of this technological shift toward more automated processes. Enhancing efficiency and reducing downtime are key in factory automation, and using linear motion systems with linear bearings are essential for this progress in manufacturing.

Linear motion systems continue to advance, with developments such as self-lubricating bearings, making systems even more effective. Linear guide systems incorporating linear bearings will shape the future of manufacturing, healthcare, transportation, and many other industries. Their adaptability, reliability, and capacity to handle diverse tasks make them not just components but keystones upon which future machinery will be built to increase efficiency, provide greater accuracy, and reduce downtime.

Linear Bearings From NSK Automation

Working with NSK to develop the ideal linear guide system for your unique application and industry will help you achieve smooth and accurate systems for all your needs. NSK linear guides can be customized, are highly rated for reliability, and are built with integrity. Let NSK help you determine the right system for optimal functionality in your industry.