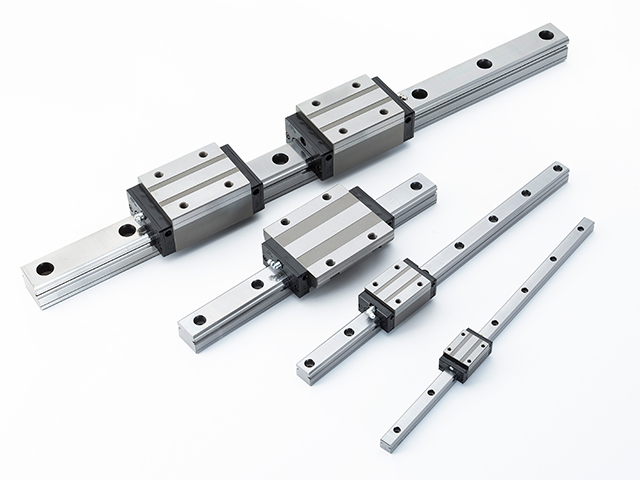

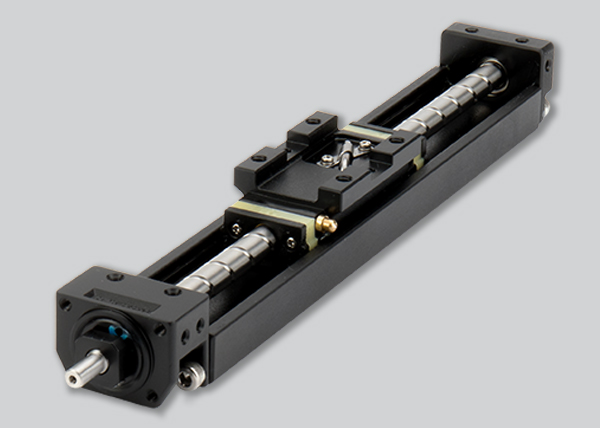

Linear slide rails are support devices that are used to help carry loads and ensure straight and level linear motion. A linear slide rail is designed to provide support to the free motion of a carriage in one linear direction. There are several different types of linear slide rails that can be customized to the needs of a specific application. As linear slide rails provide low friction, high accuracy, substantial load-bearing capacity, and smooth motion, they are a popular choice for implementation in a variety of applications across several different industries.

Linear slide rails are support devices that are used to help carry loads and ensure straight and level linear motion. A linear slide rail is designed to provide support to the free motion of a carriage in one linear direction. There are several different types of linear slide rails that can be customized to the needs of a specific application. As linear slide rails provide low friction, high accuracy, substantial load-bearing capacity, and smooth motion, they are a popular choice for implementation in a variety of applications across several different industries.

Types of Linear Slide Rails

There are several different types of linear slide rails that all have advantages in a linear motion system.

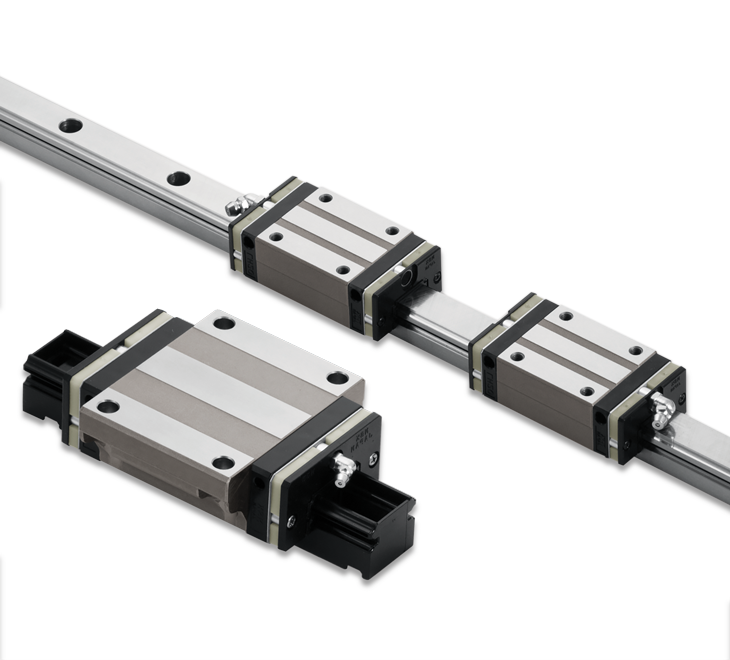

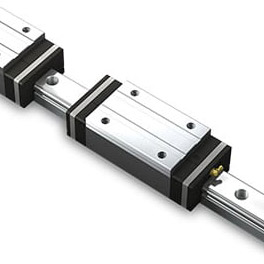

Ball bearing slide rails are used to reduce friction and allow smooth motion without damage to the object. The ball bearings move in the metallic tracks between the support rails, allowing motion with minimal friction. The ball bearings are typically fabricated from steel and are housed in a casing. Ball bearing slide rails are often used in machinery that requires a high degree of precision. The recirculating bearings connect the rail and bearing carriage with limited contact, meaning that vibration, friction, and noise are greatly reduced. This allows the machinery to both accelerate and decelerate rapidly when necessary with high accuracy. However, maintenance and lubrication are required to keep the motion smooth and accurate over time, particularly in environments where contamination from dust and dirt is possible.

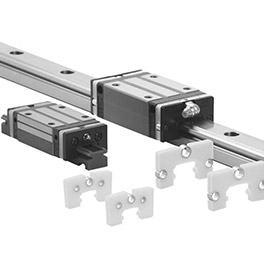

Roller bearing slide rails consist of two rails, each with a roller. They are designed to fit together and use the rolling element to achieve smooth linear motion along the rail. Roller bearing slide rails are more economical than ball bearing slide rails, but do not provide the smooth operation and high degree of precision that is present in ball bearing slide rails. Roller bearing slide rails have a shorter lifespan than ball bearing slide rails. However, in applications that do not require a high degree of precision, the lower cost of a roller bearing slide rail when compared to a ball bearing slide rail is often worth the decrease in accuracy. Roller bearing slide rails are often used in heavy equipment and machinery, the agricultural industry, and motors and engines.

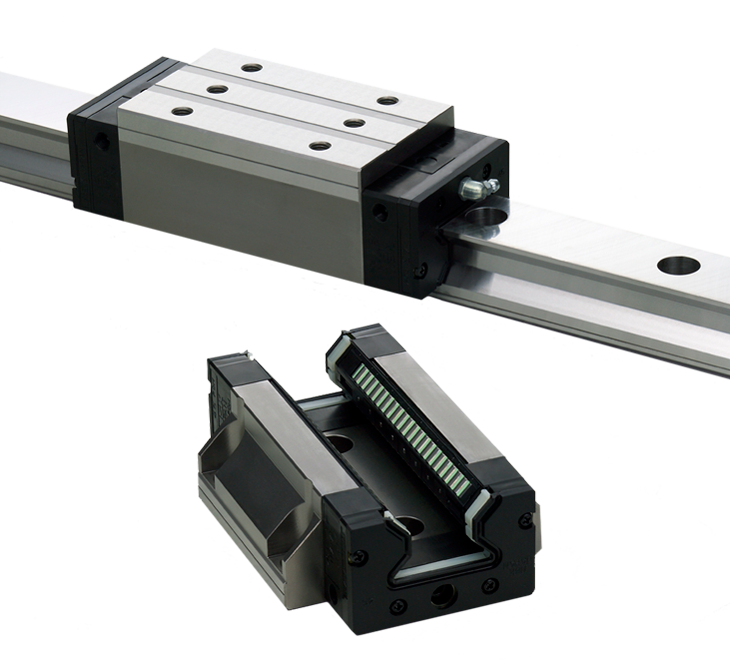

Plain bearing slide rails have simple design features. Rather than using a rolling motion, as roller bearings and ball bearings do, they slide along the rail. Plain bearing slide rails are compact, lightweight, quiet, and often less costly than other options. Plain bearing slide rails can be made from a variety of materials, and many plain bearing slide rails have lower lubrication requirements than rolling elements such as rollers or ball bearings. Some materials, such as composite or plastic plain bearings do not require lubrication at all, and therefore are ideal for many industries and applications such as laboratory automation, food processing, and packaging machinery, where lubrication has the risk of contamination.

Components of Linear Slide Rails

Linear slide rails are composed of several different components.

Linear guide rails are usually made from high-strength, hardened, and galvanized steel to resist corrosion. Steel has the necessary strength for a long lifespan and resists cracking. However, there are linear slide rails that are made from other materials such as carbon steel, stainless steel, composites, and polymers, which are often coated with self-lubricating coatings. Whatever material is used will be designed for low friction during linear motion. Linear slide rails are often treated with additional coatings to further resist corrosion, seal out contaminants, and allow for use in a variety of environments. Keeping the seals constantly lubricated is the best way to keep the rail functioning well during heavy use. Linear slide rails are able to be customized for the exact length needed for each application.

Linear slide carriages work with rails and sliding elements as part of the linear guide system. Linear slide carriages can be used either individually or in combination with multiple slide rails for more complex linear motion systems. Unlike linear rolling slides, where linear bearings will be recirculated through the carriages, the slide carriage is designed to fit onto the rail directly with low friction. The load for a linear slide rail is usually determined by the load capacity of the linear slide carriage itself, and linear slide carriages often have high load capacity when compared with other options. Linear slide carriages do typically require lubrication to function well within a linear guide system and keep friction reduced during motion.

In a linear slide system, sliding elements are used instead of rolling elements. The materials and coatings used have a low coefficient of friction and lubrication to enable motion without the need for rolling elements. Plain sliding elements are often made of composite materials which are considered to be dry lubrication, with no metal-to-metal contact between the sliding surfaces. As the composite material is abraded, the worn particles become the lubrication. When plastic is used for the sliding element, the plastic acts as an insulator, and similar lubrication properties are seen. Pressurized air or other types of fluid can be used for lubrication as well to provide motion that is nearly frictionless, which is needed in high precision applications.

Improve Efficiency with a Linear Slide Rail

With less friction than other options for linear motion systems, linear slide rails require less energy to move a load, and greater efficiency is increased.

Optimizing Load Capacity and Ratings

For the greatest efficiency, load capacity must be optimized.

- Load Distribution

Overloading a linear slide rail can cause failure. Even load distribution is essential for optimal performance. Working with the engineering team during the design of your linear motion system can help determine the best configuration for even load distribution for your application that will not add strain to any of the elements.

- Dynamic Load Considerations

The dynamic load capacity refers to the maximum weight that can be supported by a structure when subject to movement. Calculating dynamic load capacity is done by factoring in the built-in preload, weight supported members, and the effect of acceleration due to vibration or motion. For optimal performance, it is crucial to make sure that dynamic load capacity is calculated accurately by the engineers working on the linear motion system to be implemented.

- Balancing Speed and Load

Finding the optimal balance is important, as this will have an impact on both efficiency and longevity.

Enhancing Precision and Accuracy

- Tolerance Calibration

Tolerance calibration is the maximum acceptable deviation between the standard and the calibrated device. For optimal accuracy, especially in applications that require a high degree of precision, calibration techniques are crucial.

- Regular Maintenance for Accuracy

Although linear slide rails have relatively low maintenance requirements, scheduling regular inspections is recommended to ensure that the system is still functioning optimally. Depending on the environment in which the linear slide system is implemented, regular cleaning to remove dust, dirt, and other contaminants is important. NSK has several lubrication practices recommended depending on the materials used and application of the system, and it is important to follow these guidelines for optimal system performance.

- Feedback Systems

The integration of feedback devices, such as closed-loop systems, incorporate positional feedback for improved accuracy. A closed-loop system will read the output signal of a system using a sensor and pass that signal to the controller.

Advantages of Linear Slide Rails

Linear slide rails have many advantages over other linear guide systems. Precision and accuracy, smooth and quiet operation, a high-load capacity, durability and longevity, ease of installation, customization capabilities, versatility across industries, low friction, energy efficiency, and compatibility with automation are all benefits of utilizing linear slide rails.

Precision and Accuracy

Advantage: Precision and accuracy mean that the linear motion can be relied upon to perform exactly as expected, every time. While all applications require a degree of precision and accuracy, high precision is critical in several key industries. Linear slide rails offer high precision and accuracy in linear motion, making them ideal for applications where tight tolerances and exact positioning are crucial. Linear slide rails minimize any play or backlash, ensuring consistent and predictable movement. Exceptional precision is crucial in applications such as CNC machining, 3D printing, and laboratory automation equipment.

Smooth and Quiet Operation

Advantage: While it may not always be noticed in industrial applications, quiet motion is necessary in certain applications. Linear slide rails, especially those equipped with ball or roller bearings, provide smooth and quiet operation. This is beneficial in applications where noise reduction is important, such as medical devices and consumer electronics. Even when noise is not a major concern, smooth motion is needed in nearly every application that relies on a linear motion system. Smooth motion is achieved by ensuring low-friction motion between the elements of the linear motion system. When friction is reduced, the movement becomes smoother and noise is significantly reduced.

High Load Capacity

Advantage: Load capacity is a critical element of a linear motion system. When a linear motion system is overloaded, not only is efficiency and accuracy greatly reduced, but the system itself will have a high rate of failure. Linear motion systems need to be able to carry substantial loads while maintaining stability and reliability. Linear slide rails are designed to handle high loads, making them suitable for applications in many industries that deal with heavy loads, including heavy-duty machinery and equipment. Before implementing any linear motion system, it is important to calculate the load capacity, including dynamic load capacity, to ensure that the system will be able to handle the necessary force. In many cases, when a linear motion system fails, it is due to an imbalanced or overloaded system. The high load capacity of linear slide rails makes this much less of a concern.

Advantage: Load capacity is a critical element of a linear motion system. When a linear motion system is overloaded, not only is efficiency and accuracy greatly reduced, but the system itself will have a high rate of failure. Linear motion systems need to be able to carry substantial loads while maintaining stability and reliability. Linear slide rails are designed to handle high loads, making them suitable for applications in many industries that deal with heavy loads, including heavy-duty machinery and equipment. Before implementing any linear motion system, it is important to calculate the load capacity, including dynamic load capacity, to ensure that the system will be able to handle the necessary force. In many cases, when a linear motion system fails, it is due to an imbalanced or overloaded system. The high load capacity of linear slide rails makes this much less of a concern.

Durability and Longevity

Advantage: When integrating a linear motion system, having a long lifespan offers a definite advantage. When a system can be relied upon, maintenance needs decrease and downtime is minimized. Linear slide rails are often constructed with durable materials and coatings, ensuring a longer lifespan and reduced maintenance needs compared to some alternative systems. Depending on the materials and environment in which the linear slide system is installed, maintenance needs are extremely low, often just requiring occasional inspection and lubrication. With so many self-lubricating options, durability is increased even more. Having a reliable system can make a big difference in efficiency, and linear slide rails offer a definite advantage.

Ease of Installation

Advantage: Linear slide rails are almost always designed for straightforward installation. This can lead to time and cost savings during the setup of automated systems. Standardized mounting patterns and interfaces will simplify installation even further, which will allow for faster integration, increased productivity, and reduced downtime. Even customized linear slide rails can be installed very easily.

Modularity and Customization

Advantage: Linear slide rail systems often offer modularity and customization, allowing users to customize the length, configuration, and accessories based on specific application requirements. Because linear slide rails are so easily customized, they are able to adapt to any needs your industry may have for a specific application. For research and development, prototyping, and niche applications, the customization of linear slide rails offer a huge advantage. The materials of each component can be customized as well, allowing linear slide rails to work in different environments where contamination, corrosion, and durability may be a concern. Knowing that the solution can be designed to fit the exact needs makes implementing the linear motion system easy.

Versatility Across Industries

Advantage: Linear slide rails find applications in various industries, including manufacturing, automotive, aerospace, medical, and electronics, showcasing their versatility for diverse use cases. As linear slide rails are highly customizable, they can be precisely engineered for any needs that an industry may require from their linear motion system. Linear slide rails are able to be so versatile as they offer the precision and accuracy needed for certain industries along with the smooth and low-friction motion required by others. Having a high-load capacity ensures that a linear slide rail will be able to meet any potential load bearing needs, even in the most heavy applications, but the compact design ensures they can be integrated into very precise systems.

Low Friction and Energy Efficiency

Advantage: Linear slide rails, especially those with advanced lubrication systems, can reduce friction, leading to a smoother operation. Smooth operation is necessary in most applications, but can be critical in applications where low friction is necessary for precision and accuracy. Increased efficiency is also important when energy consumption is a concern. Linear slide rails often require less energy to operate when compared with other linear motion systems. Energy savings and a reduced environmental impact are strong benefits of choosing linear slide rails.

Compatibility with Automation

Advantage: Linear slide rails integrate well with automated systems and robotics, proving precise linear motion control necessary for the functioning of these systems. As automated systems are becoming more prevalent in a variety of industries, knowing that linear slide rails are easily able to work within these systems allows for continued advancement of technology in many different industries.

Applications of Linear Slide Rails

There are many applications where linear slide rails are the optimal choice.

Industrial Automation

Linear slide rails are often used in industrial automation applications. Automated machinery is becoming more prevalent in a variety of industrial settings, which allows for greater efficiency and consistency in machining due to the accuracy, precision, and repeatability of linear motion. Linear slide rails are also used in conveyor systems that can be found in industrial settings, as they are capable of high-load capacity and can move goods and equipment smoothly through the facility. Material handling equipment also benefits from the use of linear slide rails, as the low friction and high precision they provide ensures that all materials are handled correctly with little room for error

Electronic Equipment Manufacturing

Electronic equipment manufacturing requires a high degree of precision and has low tolerance for friction and vibration. Linear slide rails are the advantageous choice for electronic equipment manufacturing. Electronic equipment manufacturing requires extremely high levels of accuracy and stiffness in order to manufacture high-quality products. Automated testing systems utilize linear slide rails as part of their linear motion systems, relying on the smooth motion, low vibration and noise, and high precision they provide. Semiconductor manufacturing is another application in electronic equipment manufacturing that can benefit from using linear slide rails as the main component in a linear motion system. As the linear slide rails require little maintenance, the electronic manufacturing can be completed with consistent reliability.

Medical Device Production

The medical device industry is making use of linear guide systems in both diagnostic and surgical equipment as well as equipment for patient transport and other medical office equipment. The medical industry is highly regulated, and any linear motion system needs to operate consistently with minimal downtime. Linear slide rails contribute to the high precision and smooth movement control in both the manufacturing and use of medical equipment, including medical imaging equipment like CT scanners, MRIs, X-ray technology, laboratory automation, and robotic-assisted surgery systems. As the medical field and diagnostic and treatment methods continue to advance, especially in robotic surgery and advanced diagnostics, linear slide rails will become even more critical. Low friction, high precision, and smooth motion are all essential in the medical equipment industry.

Emerging Trends in Linear Slide Rail Technology

Linear slide rail technology continues to advance as new trends emerge.

Integration with Smart Systems

Predictive maintenance techniques are designed to help determine both the condition of equipment and timing of maintenance to minimize downtime and increase efficiency. Tasks are only performed when needed and warranted. Smart systems use sensor technology and data collection and analysis in order to make use of predictive maintenance practices. Smart systems are meeting the increasing demand for greater connectivity and an increasingly digitized system. The smart system will detect any changes within the system and alert the operator what maintenance, repair, or inspection should take place before a failure could occur, which will reduce downtime. Embedding sensors into the linear guide system itself can incorporate functions that were previously external. Integration into Smart Systems will provide greater ease of use and visibility into the operation.

Lightweight Materials

With the advancement in lightweight materials, such as composite and polymer, that can make up a linear slide rail, there is a positive impact on the overall efficiency of the linear slide rail and linear guide system as a whole when compared with the use of traditional materials such as stainless steel.

Aluminum, carbon fiber, and composite materials are very effective in applications, such as automotive or aerospace, where the weight of the linear guide system needs to be minimal. When the weight of the rail is reduced, the overall system weight can be reduced while still maintaining the rigidity, low friction, and high accuracy required.

Choosing the ideal linear slide rail for your project is essential when you are implementing a linear motion system. Before choosing the components, it is important to know the exact needs of your application, including the load capacity, precision needs, friction sensitivity, and the environment in which the linear motion system will be used. Linear slide rails can be customized to the exact needs of your application, so before finalizing your plans, consult with our engineering team about the ideal linear motion system. The skilled team at NSK can help you find the right components to build the exact system that is able to meet all your requirements.