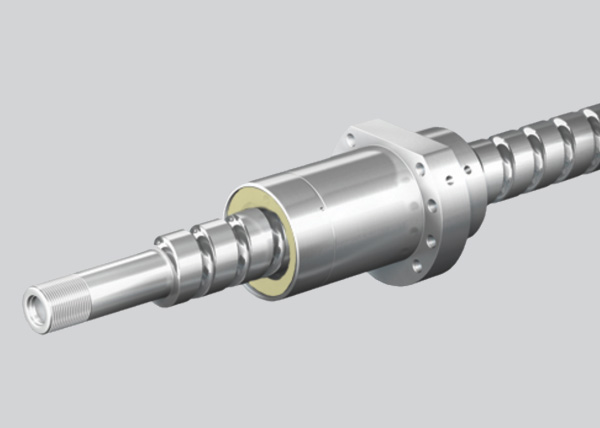

Ball Screws

Acknowledged as the global leader in ball screw design, engineering and manufacturing, NSK offers precision-ground units in standard and custom configurations for a vast array of applications. From heavy industrial manufacturing to life-critical surgical robotics, designers and producers depend on the superlative precision, repeatable accuracy, and extreme durability of NSK ball screws.

- High rigidity, smooth and near-silent operation

- Precision machined for C0 to C7 accuracy grades, from miniature to ultra large sizes

- Pioneering friction control technology for high efficiency and low power consumption

- Local manufacture for fast shipping and deployment

Ball Screw Range

* Quick ship time lines vary based on product. Consult NSK for details.

Ready To Ship 3-5 Days

NSK’s Quick Ship Program ensures quick access to Linear Guides and Ball Screws in most sizes within 3-5 days.

Offering rapid fulfillment across the US and internationally. Need modifications? Customize NSK Quick Ship parts to fit your exact specifications. Switch to NSK today for fast, dependable service that keeps your operations seamless.

Lubrication Solutions and Support Units

K1™ Lubrication Unit

- Long term maintenance-free service life: up to 5 years or 10,000 km

- Dramatically reduce maintenance cost

- Extended life in severe operating conditions

- Compliant with US FDA hygiene standards

X1 Sealing System

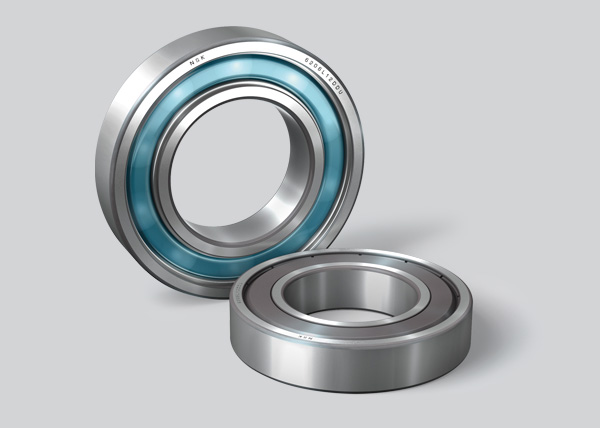

Molded Oil Angular Contact Ball Bearings

- Provides continuous supply of lubrication oil

- Clean environment with grease-free property and no oil refilling

- More than twice operating life with lubrication, in water or dust-contaminated environments

- Achieves extended maintenance-free performance providing continuous supply of lubricant

- Available for high-speed applications

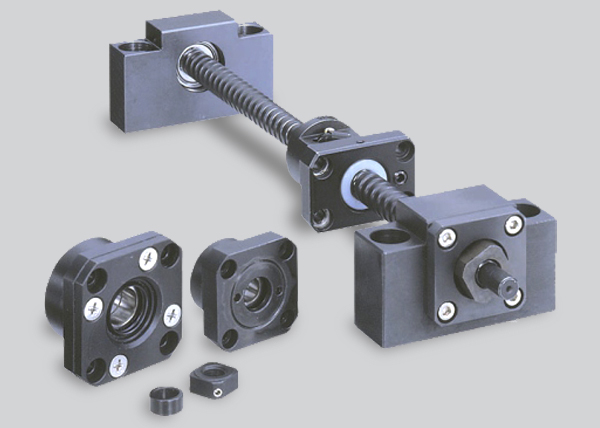

Ball Screw Support Units for Light Loads

- Support unit for light loads and small equipment

- Align with standard angular contact ball bearings

- Low dust emissions

- Ideal for clean environments

- Low profile type available

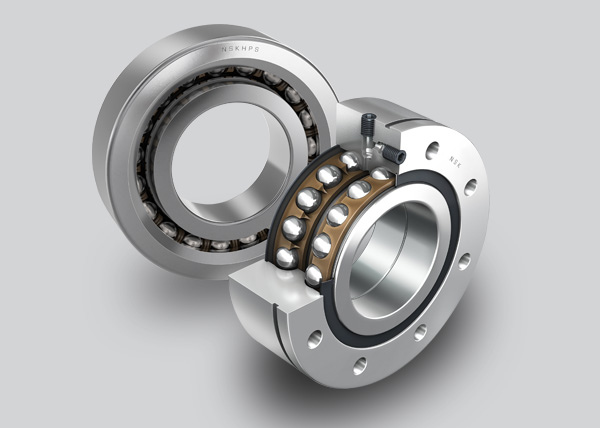

BSBD Support Units for Heavy Loads

- Support large axial forces

- Support axial load in 2 directions

- Reduced friction and heat generation

- Greased for life

- Relubrication of bearing during operation if required

- Installation ready

- Preload already set and achieved when lock nut is tightened

Case Study: Reducing Costs in Automotive Machining Center

Technical Challenge

A worldwide manufacturer of automotive components was experiencing significant unplanned downtime due to the failure of the ball screws in their machining center. This had a major effect on manufacturing output, resulting in increased costs and reduced machine reliability.

NSK Ball Screw with High-Performance x1 Seal Design

NSK Solution

NSK analyzed three of the failed ball screws to determinate the main reason for the failures, and developed a special design that improved the performance characteristics, especially the high-performance sealing design. Reduced machine downtime and a substantive increase in ball screw life achieved a cost savings of $284,365.

Integrated Mechatronic Systems Solutions

Enabling automation in motion and control

Our local integration and manufacturing teams will collaborate closely with you through all aspects of design, provide intensive project management and extend comprehensive technical support.

Design and Development

- system design proposal with

CAD model - component failure analysis and benchmarking

- material technologies

- applications simulation

Project Management

- design review – as many as 5

- quote – non-recurring engineering, prototype, full production

- prototype demonstration

- test report

- lead time/production schedule

- individual system test before shipping

After Sales Service

- on-site support for system installation

- training

- bill of materials for replacement parts