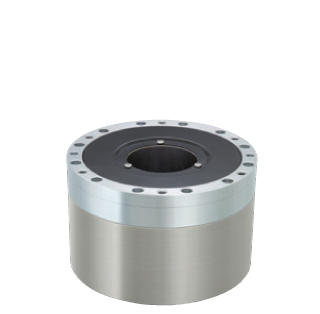

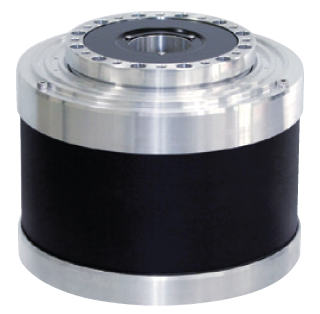

Direct Drive Megatorque™ Motors

With remarkable positioning resolution of over 2.6 million counts per turn, the NSK Megatorque Motor Series is ideal for a range of indexing, automation, and robotic applications where speed, compact size, and accuracy are paramount. They feature precision-machined crossed roller bearings for outstanding dependability and maintenance-free running.

- Extremely high resolution, 2,621,440 counts per turn

- High load capacity, over 2000 lb radial and axial

- High Torque, over 125 ft-lb max output

- Speed up to 600 rpm

- Compact and lightweight system integration

- Eliminates backlash and homing

- Complete assembled unit with frame, NSK bearings, cables

- Performance flexibility compared to CAM tables or Index tables

- Operated by NSK drive or COPLEY Controls ETHERCAT drive

- Magnetic encoder motor available with BISS communication, industry standard protocol

Direct Drive Motor: In Action

Watch the Direct Drive Motor’s performance and precision in this quick demo

Direct Drive Megatorque™ Motors Range

|

|

|

|

|

||||||||

|

SERIES |

PS |

PN |

PNZ |

PX3 |

|||||||

|

TORQUE RANGE |

PS1 |

PS3 |

PN2 |

PN3 |

PN34 |

PN4 |

PN44 |

PNZ3 |

PNZ4 |

PX3 |

|

|

150 - 200 (N-m) |

180 (112) |

175 (137) |

|||||||||

|

100 - 150 (N-m) |

135 (95) |

135 (111)5 |

130 (120) |

||||||||

|

50 - 100 (N-m) |

90 (170) |

||||||||||

|

60 (136) |

|||||||||||

|

30 - 50 (N-m) |

45 (85) |

45 (97)5 |

40 (100) |

50 (130) |

|||||||

|

20 - 30 (N-m) |

30 (103) |

||||||||||

|

18 (135) |

15 (85) |

||||||||||

|

10 - 20 (N-m) |

12 (110) |

12 (35) |

|||||||||

|

0 - 10 (N-m) |

6 (85) |

||||||||||

|

3 (63) |

|||||||||||

|

OUTPUT SHAFT DIA (mm) |

100 |

150 |

130 |

155 |

155 |

205 |

205 |

135 |

170 |

105 |

|

|

MOTOR OUTER DIA (mm) |

100 |

150 |

170 |

210 |

210 |

280 |

280 |

220 |

286 |

160 |

|

|

HOLLOW DIA (mm) |

35 |

56 |

36 |

56 |

32 |

50 |

32 |

44 |

37 |

35 |

|

|

DRIVER UNIT SIZE |

70 x 140 x 160 |

90 x 140 x 160 |

70 x 140 x 160 |

90 x 140 x 160 |

|||||||

|

|

|

|

||||||||

| 1 Direct Drive Motor Listings: Max Output Torque (N-m) > 18 (135) < (Motor Height mm) 2 Environment Resistant 3 High-Acceleration/Deceleration 4 Motor with brake 5 Dimension without brake | |||||||||||

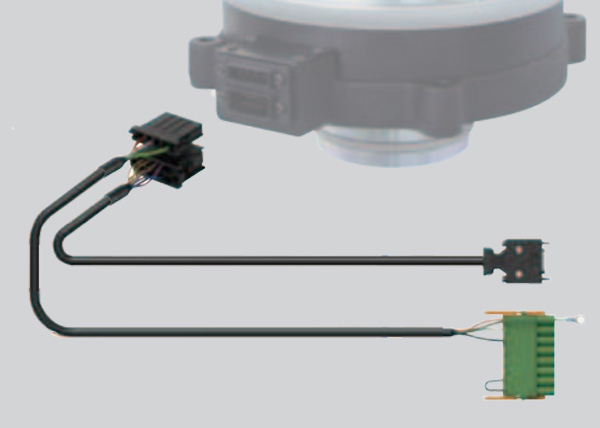

Accessories

Direct Drive Megatorque Motor Accessories

Hand Pendant "Handy Terminal"

- Available for NSK drive for programming

Cable Sets

- Can be specified for stationary operation, flexible, or high environmental resistance

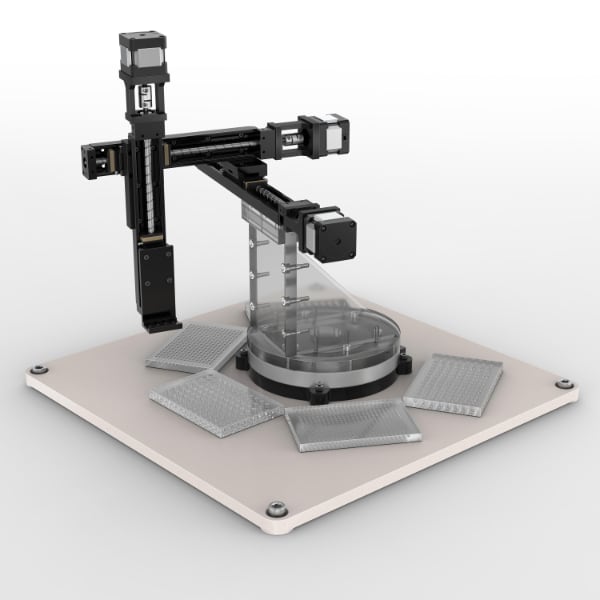

Case Study: Diagnostic system with 3-axis linear positioner and super-high-precision rotary indexer

Technical Challenge

A global manufacturer of diagnostic equipment required a custom, fully tested and assembled XYZ platform with rotational positioning to allow continuous reagent processing. Extended lifetime to ensure uninterrupted operations was essential, as was greater rigidity and smoothness over lead screw-based actuators. Specified travel requirements, load conditions and envelope dimensions for their diagnostic equipment had to be met.

NSK Direct Drive Megatorque Motor with multi-axis Moncarriers.

NSK Solution

- Robust, NSK-designed, pre-assembled diagnostic system, featuring (3) miniature Monocarriers for X-Y-Z positioning, along with sensor, sensor rail, combining brackets, motor brackets and stepper motors

- Super high resolution and torque, NSK Megatorque motor to rotate the three axis stage in small increments and discrete locations along the platform for precise positioning of the dispensing nozzle

- Equipped with K1 lubrication units for maintenance-free operation as long as 5 years or 10,000 km travel

- Execution of design validation, ensuring proper rigidity and repeatability of assembled system for the application

- Quality assurance testing of each assembled system prior to shipping

- Use domestically-made precision products

Integrated Mechatronic Systems Solutions

Enabling automation in motion and control

Our local integration and manufacturing teams will collaborate closely with you through all aspects of design, provide intensive project management and extend comprehensive technical support.

Design and Development

- system design proposal with

CAD model - component failure analysis and benchmarking

- material technologies

- applications simulation

Project Management

- design review – as many as 5

- quote – non-recurring engineering, prototype, full production

- prototype demonstration

- test report

- lead time/production schedule

- individual system test before shipping

After Sales Service

- on-site support for system installation

- training

- bill of materials for replacement parts