Toronto, Ontario, is a central hub for many industries requiring precise and efficient mechanical operations. At the core of such high-performance machinery are linear guides, which facilitate exact movements essential for various applications. With its expertise in delivering top-quality precision linear motion solutions, NSK is ideally positioned to cater to the robust industrial sector in Toronto.

The Significance of Linear Guides

Linear guides are vital in many industrial applications, allowing for smooth and accurate linear motion. These components are used extensively in manufacturing, automotive, and robotics sectors, where precision and reliability are paramount. The diversity in types and designs of linear guides—from simple slides to complex recirculating ball systems—allows them to be tailored to specific needs and environments, enhancing their applicability.

NSK Pioneering Solutions

NSK stands out with its innovative approach to linear motion solutions. The company offers an interchangeable series of linear guides, which are compatible replacements for existing systems from other brands, simplifying upgrades and maintenance. Additionally, NSK has developed the K1 lubrication unit, which is especially beneficial in highly contaminated or harsh environments like welding operations, ensuring longevity and consistent performance of the linear systems.

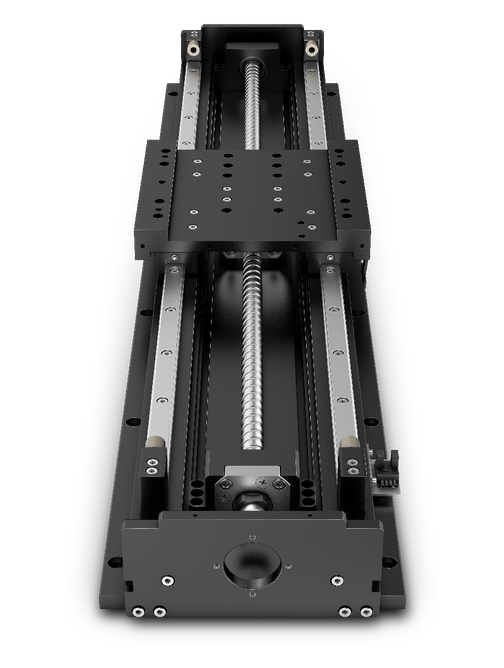

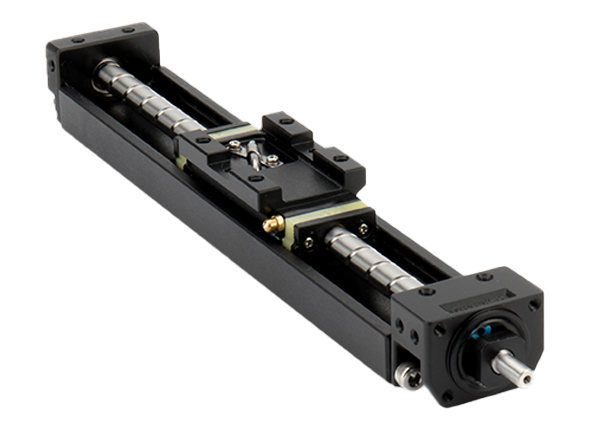

NSK’s offerings include precision-engineered machined and rolled ball screws and a variety of axis actuators, both ball screw-driven and linear motor-driven. These products underscore the company’s commitment to providing versatile and robust motion control solutions tailored to meet diverse industrial needs.

Industrial Impact in Toronto, Ontario

Toronto’s diverse industrial landscape benefits significantly from advanced linear motion technologies. NSK supports key industries, including manufacturing, automotive, packaging, machine building, and robotics. A cutting facility in nearby Brampton that can ship products as quickly as the next day, coupled with local engineering support and a substantial inventory, positions NSK as a pivotal player in Toronto’s industrial sector.

The company not only offers products but also extends comprehensive support through online resources, live engineer chats, and an online product selection and sizing tool. Their quick ship program for linear actuators and the availability of food-grade products demonstrate NSK’s adaptability to industry-specific needs.

Choosing the Right Linear Guides for Your Needs

Selecting the appropriate linear guides involves several considerations:

- Load Capacity: Understanding the load capacity is essential when selecting linear guides. These components must be robust enough to handle the static load (the weight they support at rest) and dynamic load (the load during operation). It’s not just about bearing the weight but ensuring stability and reliability under the strain of daily operations. This capability prevents premature wear and failure, essential in high-stake applications like aerospace or automotive manufacturing, where equipment failure can lead to significant downtime and increased operational costs. Thus, assessing load capacity helps in choosing components that not only fit the mechanical requirements but also contribute to the longevity and reliability of the entire system.

- Speed and Accuracy: The required speed and precision of linear guides are paramount in determining their suitability for specific applications. High-speed applications, like automated assembly lines or machining centers, require bearings and rails that maintain accuracy at elevated velocities, minimizing vibrations and noise. Conversely, applications involving intricate or delicate movements, such as robotics or aerospace, demand high precision for exact positioning. The bearings’ and rails’ design and material play significant roles in their performance characteristics. Therefore, identifying the specific needs of your application ensures the selection of linear motion components that enhance overall system efficiency and output quality.

- Environment: The operating environment is imperative in selecting suitable linear guides. Components must be chosen based on their ability to withstand various environmental conditions, including extreme temperatures, which can affect material integrity and lubrication efficacy. Contaminants like dust, debris, or chemical vapors can erode surfaces or clog mechanisms, while corrosive substances require corrosion-resistant materials to assure longevity. For instance, stainless steel or coated rails might be necessary in chemically aggressive or humid environments. Considering these environmental factors, you can select bearings and rails that maintain performance and durability, reducing the need for frequent replacements and maintenance.

- Maintenance Requirements: Evaluating the ease of maintenance and the expected lifespan of linear guides is important for operational efficiency. Components that are easier to maintain and last longer will reduce downtime and the costs associated with repairs and replacements. Maintenance-friendly designs that allow for easy access to lubricate or replace parts can significantly extend the operational life and reliability of machinery. Considering the materials’ longevity and their wear characteristics under regular use conditions helps in planning maintenance schedules that keep machines running efficiently without unexpected failures. Thus, a comprehensive assessment of maintenance requirements is vital for ensuring sustained performance and cost-effectiveness of linear motion systems.

Cost: The cost of linear guides is an essential consideration that requires balancing performance requirements with budget constraints. While higher-quality, durable components may carry a premium price, they can offer better longevity and reliability, which translates into a lower total cost of ownership due to reduced downtime and maintenance needs. Conversely, opting for less expensive, lower-quality parts might save immediate costs but can lead to increased expenses over time due to frequent failures and replacements. Therefore, it’s essential to evaluate the long-term financial impact of your component choice and select products that offer the best return on investment by optimizing both initial costs and operational expenses.

Cost: The cost of linear guides is an essential consideration that requires balancing performance requirements with budget constraints. While higher-quality, durable components may carry a premium price, they can offer better longevity and reliability, which translates into a lower total cost of ownership due to reduced downtime and maintenance needs. Conversely, opting for less expensive, lower-quality parts might save immediate costs but can lead to increased expenses over time due to frequent failures and replacements. Therefore, it’s essential to evaluate the long-term financial impact of your component choice and select products that offer the best return on investment by optimizing both initial costs and operational expenses.- Compatibility: Ensuring that new linear guides integrate seamlessly with existing systems is fundamental to maintaining operational continuity and efficiency. Compatibility issues can lead to significant engineering challenges, potentially requiring extensive modifications to machinery or even complete system overhauls, which can be costly and time-consuming. Verifying that the components match the specifications of the existing system is essential, including dimensions, load capacities, and interfacing requirements. This foresight prevents potential mismatches and operational disruptions, facilitating a smooth transition and integration of new components into the system, thus safeguarding productivity and minimizing project risks.

Engineered for Success

NSK offers comprehensive solutions for linear guides engineered to meet the diverse needs of Toronto’s industrial sectors. The company’s dedication to robust engineering support and willingness to develop customized solutions highlight its commitment to client satisfaction and technological advancement.

For businesses in Toronto seeking to enhance their operations with reliable and efficient linear motion solutions, NSK’s wealth of experience and a broad range of products offer the tools necessary for success. Leverage NSK’s application engineering expertise to meet your linear motion needs and enhance your operational capabilities.